SD Guthrie uses the GHG Protocol Corporate Accounting and Reporting Standard, GHG Corporate Value Chain (Scope 3) Standard and GHG Protocol Land Sector and Removals Guidance to calculate GHG emissions. For more information, please refer to HERE.

Zero Emission: Carbon Emission & Reduction

Greenhouse Gas (GHG) Emissions Reduction

Greenhouse Gas (GHG) Emissions Reduction

As one of the world's largest producers of Certified Sustainable Palm Oil (CSPO), we recognise the important role we play in managing GHG emissions across our operations and supply chain, to mitigate the adverse effects of climate change.

SD Guthrie has an ambitious targets validated by SBTi to achieve net-zero emissions by 2050, focusing on 3 main areas:

- Acceleration and Expansion of Renewables

- Land Use Transformation

- Enhancing Supplier Engagement

For more information on our Net-Zero Roadmap, please visit HERE.

Understanding our emissions intensity at our downstream operations can be challenging due to the range of processes and products at each business location.

Various energy saving projects were implemented across the Group’s refineries. These include projects to improve condensate recovery, heat recovery and insulation, and replacing large motors with high efficiency motors. At our refinery in the Netherlands, a reverse osmosis plant was built; reducing the amount of water, energy and chemicals needed in the plant’s operations.

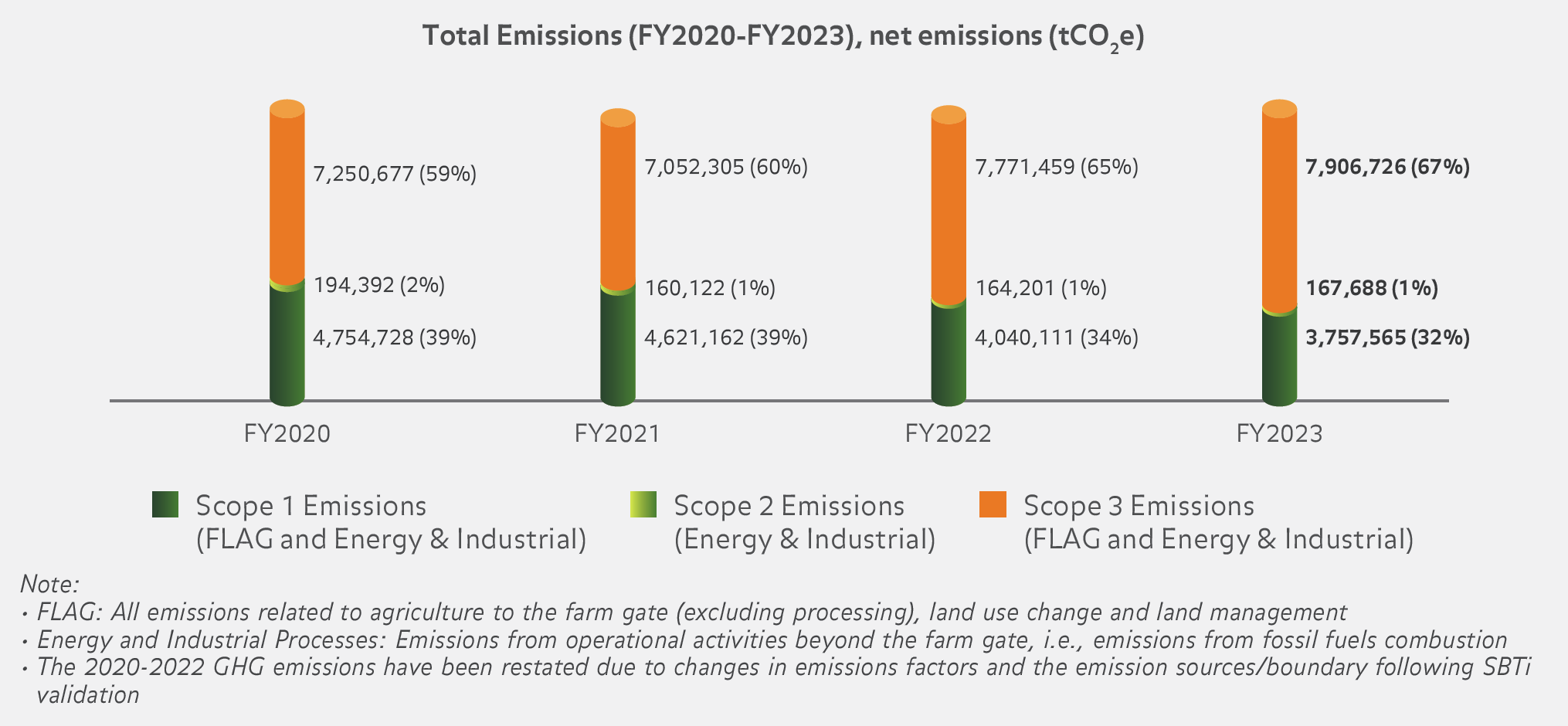

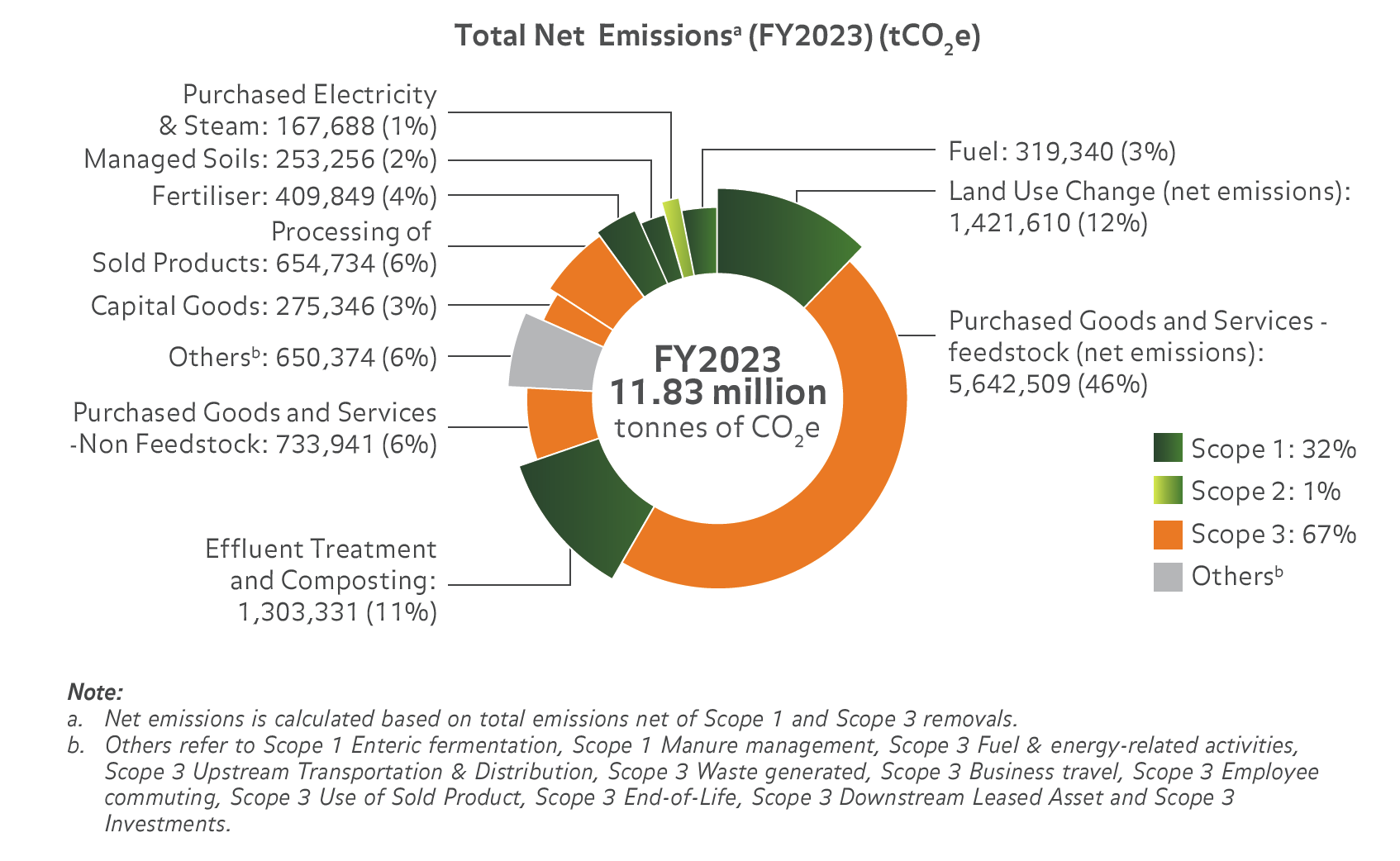

The Group actively monitors our total GHG emissions, reported in carbon dioxide equivalents (tCO2e), while accounting for carbon removals and sequestration from oil palm, rubber, and high conservation value (HCV) and conservation set aside areas. A significant portion of our net emissions comes from Scope 3 sources, particularly within our supply chain, such as purchased feedstock and other materials. We are continuously enhancing our supply chain engagement to collaborate with suppliers in addressing and reducing Scope 3 emissions.

The Group implements energy-saving initiatives to reduce reliance on fossil fuels, with a portion of our energy needs offset by renewable sources. For instance, palm fibre and shells are used in mill biomass boilers; rooftop solar installations contribute to energy cost savings, and biogas facilities at SD Guthrie’s mills—especially those with limited access to the national grid—help displace diesel consumption while mitigating methane emissions from palm oil effluent, supporting the Group’s net-zero target. The Group remains committed to increasing our use of renewable energy and minimising reliance on non-renewable sources.

| Description | FY2021 | FY2022 | FY2023 |

|---|---|---|---|

| Total energy consumption (gigajoules) | 31,024,668 | 28,513,353 | 28,978,121 |

| Energy consumed from renewable sources (%) | 86 | 86 | 88 |

| Energy consumed from non-renewable sources (%) | 14 | 14 | 12 |

Note: Energy from renewable sources includes biomass, biofuels, biogas, and solar.